Spinner Spreader Control

DirectCommand® offers simple spinner spreader control allowing for AutoSwath, variable rate application, rate control and more.

DirectCommand simplifies spinner spreader control by controlling the spinner speed, in addition to monitoring the bin level. The system reads ground speed and automatically adjusts product flow to match target application rates.

DirectCommand control modules support PWM, motorized servo, Mark IV.2, Mark IV.4 and Mark V hydraulic control valves. DirectCommand also supports application control of multiple bin spinner spreaders.

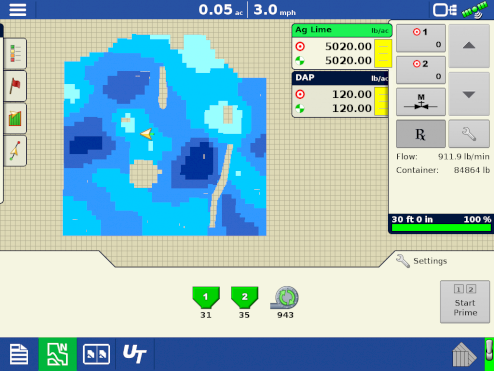

Variable Rate Application

DirectCommand allows the variable rate application of single or multiple products. The system controls application rates of liquid and granular products automatically, based on geo-referenced prescription maps.

Rate Control

Control, adjust and record field application based on manually entered target rates or by using rates from a variable rate prescription file. The system uses a flow meter signal and speed input from a radar or GPS receiver and reads up to three optional pressure sensors, eliminating the need to monitor pressure gauges outside the cab.

Additionally, enhanced calibration simplifies setup time by creating and storing calibration routines, eliminating the need to recalibrate equipment each time it's used.